Band gap of strained AlGaInP on GaAs substrate

- Input Files:

AlGaInP_on_GaAs_1D_nnp.in

- Scope:

In this tutorial we study the band gaps of strained

on a substrate. The material parameters are taken from [VurgaftmanJAP2001]. - Output Files:

strain\strain_simualtion.dat

strain\hydrostatic_strain.dat

bias_00000\bandedges.dat

Strain

To understand the effect of strain on the band gap on the individual components of the quaternary

strained tensely with respect to

strained tensely with respect to

strained compressively with respect to

strained tensely with respect to

strained with respect to

strained with respect to

strained tensely with respect to

strained compressively with respect to

strained compressively with respect to

Each material layer has a length of 10 nm in the simulation. The material layers 4), 5) and 6) vary their alloy contents linearly, i.e.

: x = 0.0 to x = 1.0 (from 10 nm to 20 nm)

: x = 0.0 to x = 1.0 (from 30 nm to 40 nm)

: x = 1.0 to x = 0.0 (from 50 nm to 60 nm)

There is no external stress applied to the structure, so Poisson’s ratio holds.

All layers are strained pseudomorphically with respect to a

The biaxial strain in the layers can be calculated with this formula:

where

The hydrostatic strain is the trace of the strain tensor and corresponds to the volume deformation:

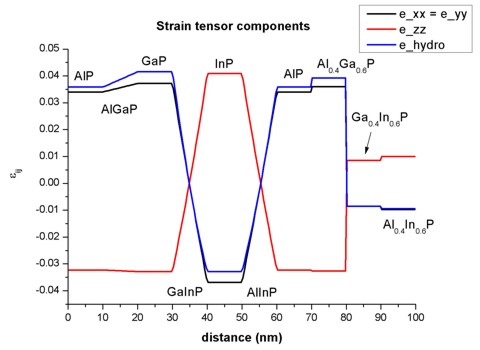

Figure 2.4.43 Strain tensor components

band gaps

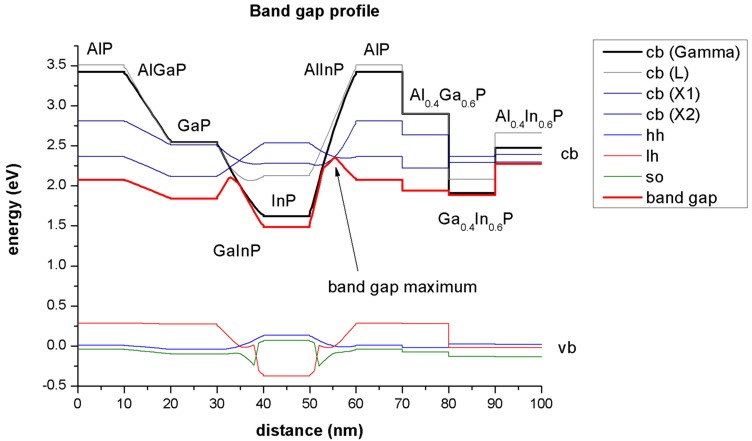

Figure 2.4.44 shows the conduction band edges at the Gamma, L and X points and the heavy hole, light hole and split-off hole valence bands.

The red line shows that band gap, i.e. the difference between the lowest conduction band minimum and the valence band maximum.

The band gap maximum occurs at

The conduction and valence band edges have been obtained taking into account the shifts and splittings of the bands due to strain and deformation potentials.

Note that conduction and valence band offsets are not taken into account in this plot. The zero of energy was taken to be the unstrained heavy hole / light hole band edge.

Due to strain, the degeneracy of the heavy and light hole is lifted. Also, the X band splits into two X bands (2-fold and 4-fold degeneracy).

In the case of tensile (compressive) strain, the light (heavy) hole band is the valence band maximum.

Figure 2.4.44 Band edge and band gap profile

Note that the material parameters include band gap bowing.

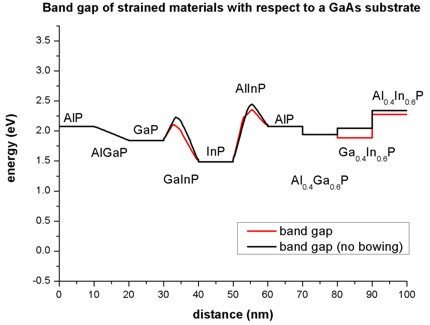

Figure 2.4.45 compares the overall band gap to the case where band gap bowing has been neglected.

Figure 2.4.45 Ban dgap profile

The nextnano++ tool supports quaternaries in comparison with nextnano³:

quaternary_constant{

name = "Al(x)Ga(y)In(1-x-y)P"

alloy_x = 0.255

alloy_y = 0.255

}

Appendix E of the PhD thesis of T. Zibold ([ZiboldPhD2007]) is related to the nextnano++ implementation of quaternaries.

Last update: nn/nn/nnnn